Life Cycle Analysis, Phases, and EPDs

In order to get started in incorporating low-carbon strategies into your buildings, one must understand the following terms: Lifecycle assessment (LCA), Lifecycle phases, and environmental product declaration (EPD).

Life Cycle Analysis

All models are wrong, but some are useful. A carbon assessment or Life Cycle Analysis (LCA) is a model with the intent of lowering carbon emissions. The usefulness is dependent on the assumptions and data used to inform the model. These models are most effective when assessing relative performance between options or quantifying the absolute order of magnitude of an impact to determine allocation of resources and inform decision making.

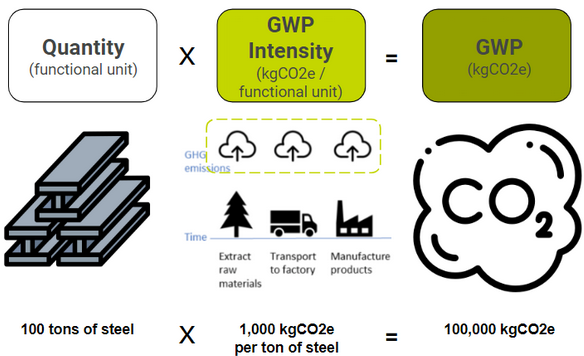

At the most basic level of understanding, one can think of an LCA as taking inventory of material quantities and multiplying by a corresponding global warming intensity (Figure 1).

Figure 1. CALGreen Embodied Carbon Series: Whole Building Life Cycle Assessment for Code Compliance

LCA can be broken down into four basic steps:

- The Goal and Scope of an analysis define the rules.

- An inventory of building materials by type and quantity that are a part of the scope defined in Step 1.

- Impacts of each material itemized for the inventory

- And results, which should be studied for errors along with conclusions documented toward the goal defined in Step 1.

Defining your goal and scope is important to informing the data that is collected and tool required for LCA. This definition establishes “functional equivalence”, which is important when comparing analyses. This is a way of saying that we compare “apples to apples”—both in terms of physical scope (e.g. structure and enclosure) as wall as life cycle phases (e.g. A1-A5).

The intent of LCA is reduce embodied carbon emissions through holistic, performance-based approach that allows teams the flexibility to optimize through reduction options unique to each project such as partial reuse, design efficiency, alternative material selection, and procurement of low-carbon building products. At different phases of the project, it may be appropriate.

“I want to understand where to focus my decision making.”

Estimate the absolute impact to identify primary influences.

“I want to understand which choice is better.”

Estimate the relative impact of comparable, “functional equivalent” options.

Life Cycles

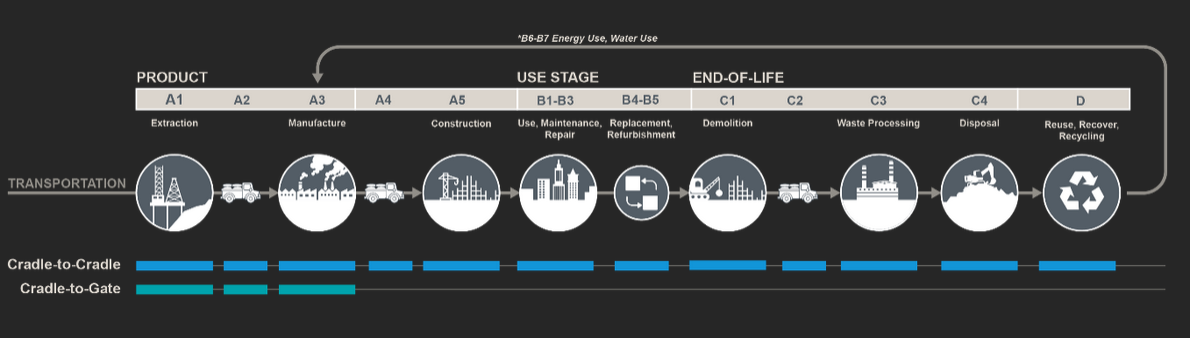

Life cycle phases (Figure 2) offer a consistent language for talking about embodied carbon impacts (BS EN 15978:2011). Phases are broken up into Stage A, Stage B, and Stage C.

Stage A: The 'Product' stage: the raw material supply (Module A1), transport (Module A2), manufacturing (Module A3), transport to the construction site (Module A4), and construction & installation (Module A5). A1-A3 is what is most commonly provided in an EPD.

Stage B: The 'In-Use' stage: the use (Module B1), maintenance (Module B2), repair (Module B3), replacement (Module B4), refurbishment (Module B5), operational energy use (Module B6), and operational water use (Module B7). Operational impacts or often excluded from the scope of embodied carbon study. However, this stage is important when considering interiors, which are replaced frequently over the life of the building, or MEP emissions, where refrigerant leakage happens during use.

Stage C: The 'End-of-life' stage, which includes the deconstruction and demolition (Module C1), transport (Module C2), waste processing (Module C3), and disposal (Module C4).

Module D: The 'Beyond-Life' module includes all benefits and loads that occur outside of the system boundary of the system. This module is often reported separately.

Figure 2. Life Cycle Phases Summary

Environmental Product Declarations (EPDs)

Environmental Product Declarations (EPDs) are eco-labels that transparently and objectively report the environmental performance of a product or service from a life cycle perspective. These are environmental nutrition labels for manufactured products that will tell you how much embodied carbon, as well as other impact categories, is required to make a functional unit (e.g. pounds or cubic yards) of a given product.

An EPD is the result of a life cycle assessment (LCA) and is third-party verified. In order for EPDs to be standardized and compared, Product Category Rules (PCRs) have been developed which define the rules for how to perform the LCA that makes an EPD.

There are three types of EPDs:

- Industry average: an average of multiple manufacturers, typically developed by a trade organization.

- Product-specific: an average of multiple facilities that make the same product, typically developed by a single manufacturer.

- Facility-specific: data for a single product developed at a single facility (most specific).

EPDs for structural materials typically only include Modules A1-A3 “cradle-to-gate” data. Other, background data sources (typically found in LCA tools or software) are used for the remaining modules.

Reporting Studies

Because studies may vary in scope, goal, or intent, it is very important that published findings include information such as physical elements included (e.g. structure and enclosure) as well as the LCA data that was used (e.g. A1-A3).