UCLA and UCSD's Surplus Programs and Interior Reuse

Waste is a problem on college campuses. Every year, students throw away 640lbs on average. UCSD and UCLA are tackling waste with Surplus Sales and Surplus Stop, respectively.

Executive Summary

Construction and Demolition (C&D) waste contributes as much as twice as much as municipal waste, largely in the form of replaced furniture, fixtures, and finishes. Interiors’ embodied carbon is crucial for universities because it represents a significant portion of their overall carbon footprint, especially given the frequent renovations and updates to campus buildings.

UCSD’s Surplus Sales started back in 1983 with “one employee and a truck” and has grown to process over 1.5M lbs. of product annually. At UCLA, the salvage program is in its first years and looks to grow. Both offer facility as well as students an alternative to the landfill.

LCA Results

Surplus Programs provide an alternative way to source materials for university departments. Each reused chair saves 80 kgCO2e on average. That means reusing a classroom of chairs is like taking a car off the road.

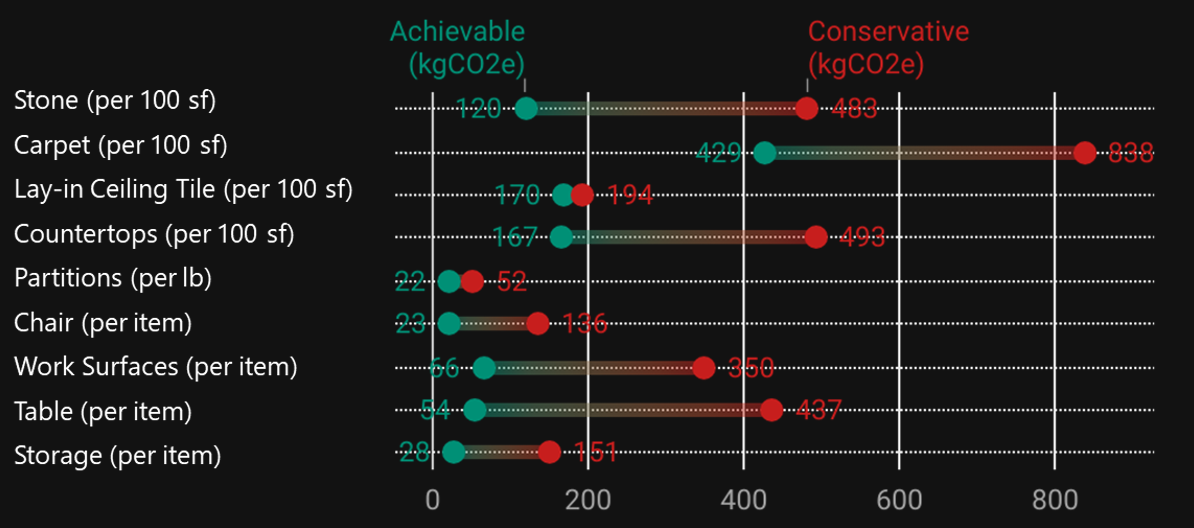

Interiors are an emerging field of research when tracking embodied carbon. While manufacture data is limited, the EC3 tool can be a useful place to find data and suppliers willing to collaborate on design requests. For new design or interior fit out, the team is recommended to request EPD data from suppliers to better understand the impact and make informed decisions in the future (Figure 1).

Figure 1. Environmental project declaration (EPD) data from EC3 presented as a range of kg-CO2e for interior materials.

UCSD’s Surplus Sales has also grown to offer a “custom build program” for offices. Bringing new life to this equipment could save upwards of 350 kgCO2e and be done at 1/3rd the price of new.

Reduction Visualizer

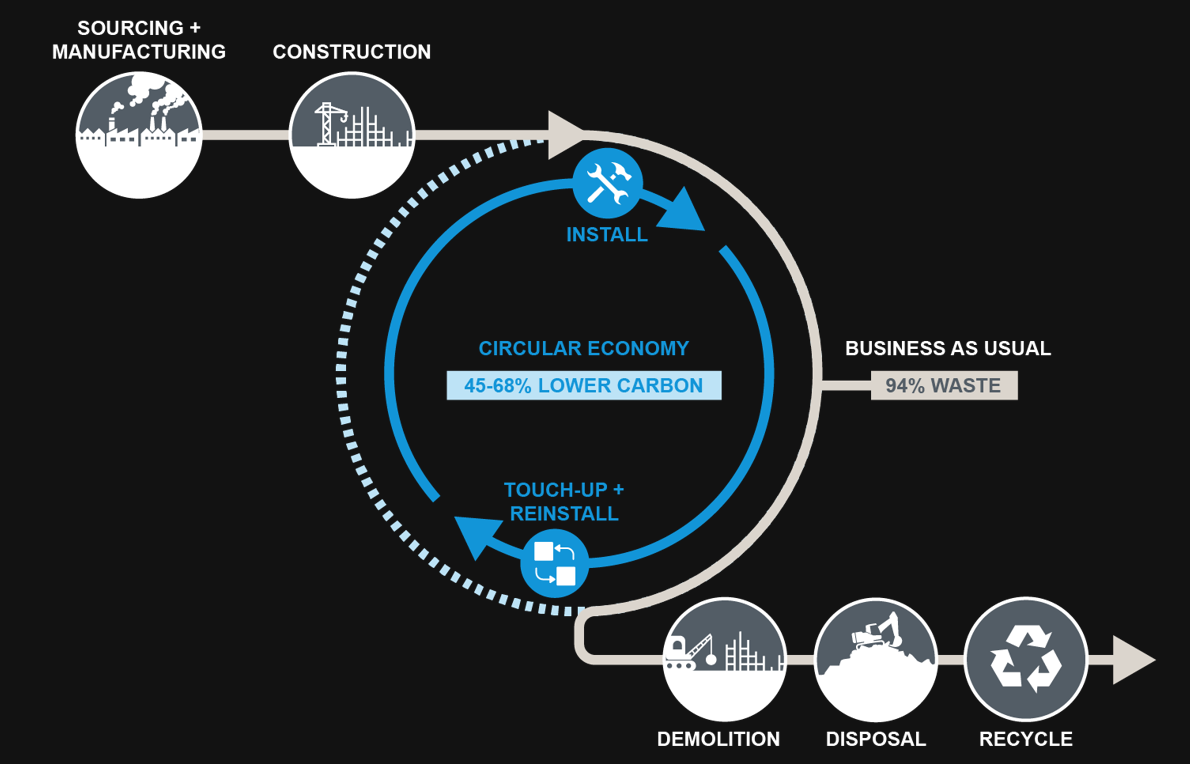

Without consideration for end-of-life, almost all of our “stuff” goes to landfill. This is the “take-make-waste” linear economy. In Figure 2. the diagram shows two potential scenarios for construction goods: a linear use of goods from sourcing and manufacturing, construction, building use, and disposal, and a second "circular economy" that reduces embodied carbon by 45-68% through touch-up and reinstall of building products.

Figure 2. How the circular economy reduces embodied carbon by 45-68%

System thinking approach can reclaim what is otherwise “waste” and reduce demand for new resources (and carbon). Some furniture suppliers offer take-back systems or reused products:

- Reseat

- Herman Miller Renew

- Davies Office

Hazardous materials limit reuse potential. Healthy materials facilitate a circular economy.

Motivation and Goals

- While embodied carbon is not calculated as part of these programs, this case study looks to highlight the co-benefit of waste diversion with embodied carbon:

- Waste reduction on campus has lead to sustainability efforts that reduce embodied carbon.

- On-campus reuse centers and take-back programs redesign systems that make up a circular economy.

- The circular economy offers potential cost savings by eliminating inefficiencies and maximizing the useful life of what is purchased. This framework also offers a lens with which to view the value of our existing buildings as material banks.

Supply Chain of Material

Where do carbon impacts of Interiors come from?

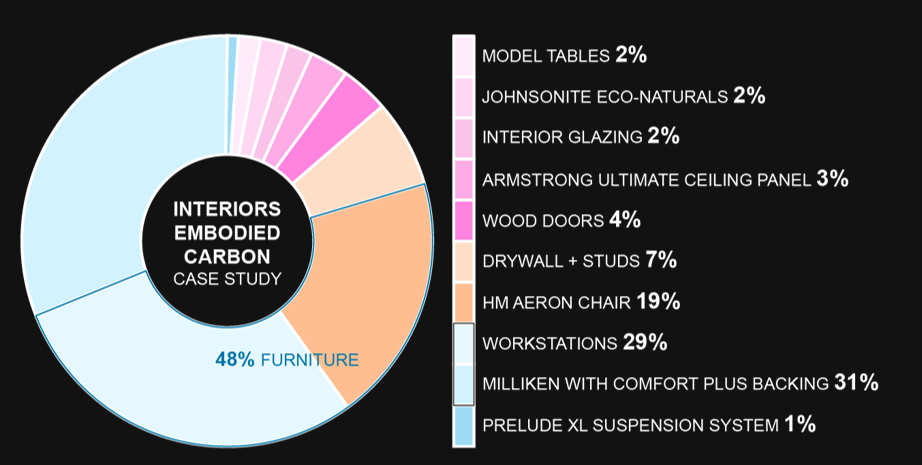

Interior embodied carbon may come from a variety of products. No one category is most responsible or the clear solution. Designers should focus on elements with high turnover, such as furniture. The Figure 3. pie chart estimates the impact of interior embodied carbon from a study by LMN. The biggest contributors are furniture (chairs and workstations) contributing 48%, and Milliken carpet contributing 31%. Other contributions from partition walls, doors, and ceiling panels.

Figure 3. LMN (2024), “15 – Interiors, Cyclical Renovations + Carbon”

Manufacturing (A3): Most product emissions come from material manufacturing. Metals are often the most intensive. Designers should look to low-carbon natural materials as an alternative.

Operations (B2-B4) and Waste (C): Interior emissions accumulate over the life of the building. Unlike building structure, interiors may be replaced every 5-10 years.

Roadblocks and Challenges

- The circular economy is still in the relatively small scale, early-stages, and faces challenges to develop:

- Industry norms prefer new products and new products are often disproportionately cheap.

- Coordination and logistics can be a challenge. In addition to collecting and storing products, there must be a demand for purchase of used products to make the economics work. Interiors are the place to start.

- Relatively few EPDs available to quantify the benefit of this work.

Design Process (Low Carbon vs Usual)

- Concept: Include material reuse in the scoping document

- Schematic Design and Design Development: Consider design for deconstruction

- Construction Documentation: Specify products with take-back programs

- Construction Administration: Work with the design team to identify reuse suppliers

Lessons Learned

- In the future, the cost of landfilling materials is likely to increase. This could incentivize the university to adapt to more robust systems of reuse to avoid such costs when maintaining the campus.

- Interior products are a starting point for material reuse given their limited performance criteria. Similar concepts could be applied to structure and enclosure materials. Future buildings slated for demolition may have a reclamation audit to assess potential reuse.

UCLA Surplus Stop and UCSD Surplus Sales

The Surplus Stop, managed by UCLA Zero Waste, is located at Parking Structure 9 and operates by appointment only. Donations from students, staff, and departments are accepted, and others within the UCLA community can take these items for free. This initiative not only reduces waste but also provides valuable resources to those in need.

UCSD

Surplus Sales is open to the public and campus clients Monday through Friday from 10 AM to 3:30 PM; walk-ins are welcome. For online auction winners and online reservation orders, please Contact us or schedule an appointment here. The Surplus warehouse is located at 7835 Trade St. San Diego Ca, 92121 Behind Ste. 100 (Northeast corner of the building). Parking is free for clients and is available near the gate entrance.