UCSB Henley Hall

Henley Hall is a 49,900 GSF building that serves as both wet and dry labs as well as lecture hall and office space. Completed in 2020, this 2021 AIA Award winner has a carbon story beyond energy efficiency.

Executive Summary

Given the high energy demands of the lab space, the design team bifurcated building program to optimize low-energy demand spaces away from sensitive lab equipment. This enabled passive systems on the eastern wing where a three-story open-air atrium allows for ambient air flow. By removing additional 20-ton VRF equipment and corresponding refrigerant, an estimated 300 tons of carbon was saved—in addition to operational savings.

LCA Results

In order to assess cradle-to-grave LCA, the team used One-Click and found that:

- Refrigerant leakage is one of the biggest contributors to global warming on account of high global warming potential.

- Alternative refrigerants are appearing on the market. For a high-pressure VRF there are three alternatives: R-410a (typical), R-32 and R-454b.

- A water-cooled chiller would provide the option of using water (GWP = 0) as an alternative.

- Though often overlooked on account of limited EPD data, embodied carbon from metals and other manufactured elements

Reduction Visualizer

Figure 1. Exterior photo of Henley Hall’s building façade. The façade is made out of glass, stone walls, and steel cladding.

The image in Figure 1. depicts the project's open air atrium and building facade. The photo showcases the steel structure, glass facade, and a stone wall which allowed for the following reductions:

- Low-energy demand occupancy moved to east wing to enable passive systems

- Shading and open-air atrium create passive environment, eliminating equipment

Motivation and Goals

- MEP embodied carbon was not a consideration of this project. A retrospective analysis and industry research offer the following recommendations:

- Hybrid VRFs should be prioritised over VRF systems due to high-pressure system leakage. Reduce distribution length, where possible.

- In offices, centralized systems have the greatest opportunity for using low GWP refrigerants.

- In, residential scenarios, if a centralised system is not feasible, prioritize a water based packaged system.

- Consider use a system performance monitoring software to identify maintenance problems early. Additionally, ensure best practice to minimize leakage at end of life.

- Of note, this project additionally reduced embodied carbon via concrete mix design and swapping out foam insulation as well as choosing to have exposed concrete as a finish to eliminate other finishes.

Supply Chain of Material

Where do carbon impacts of MEP systems come from?

Manufacturing (A1-A3): Material manufacturing emissions contribute embodied carbon similar to structural steel. Less material or higher recycled content reduces embodied carbon.

In-Use (B1): Avoided equipment with refrigeration prevents leakage of high-GWP.

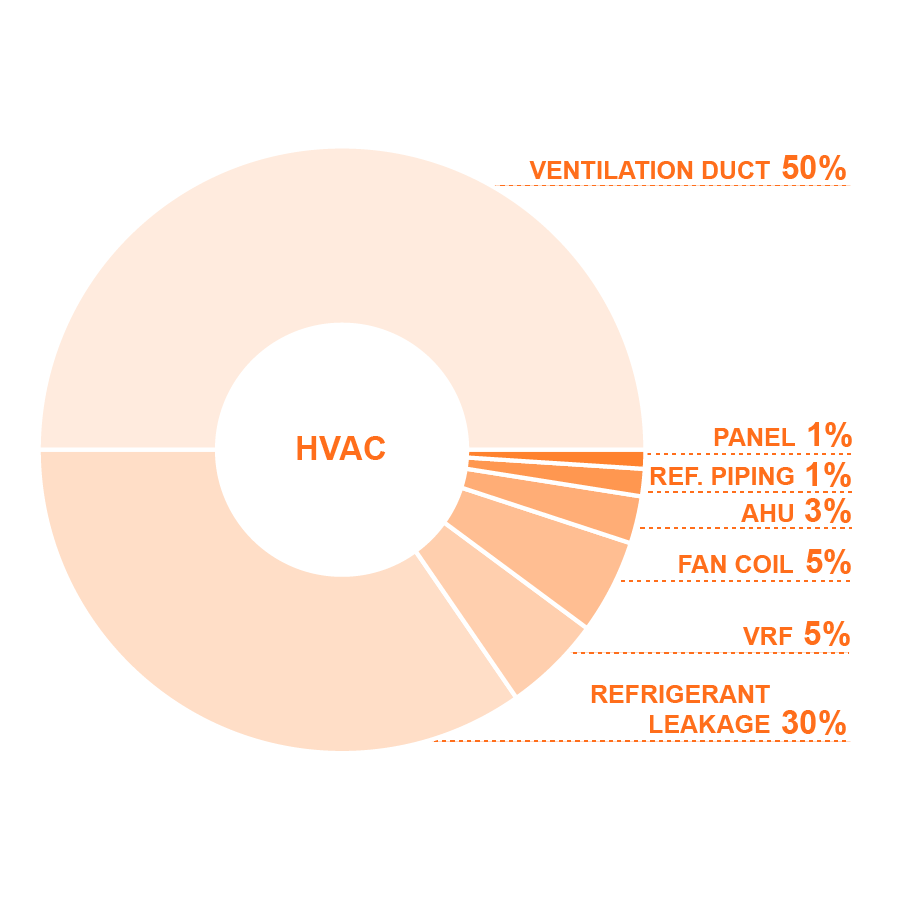

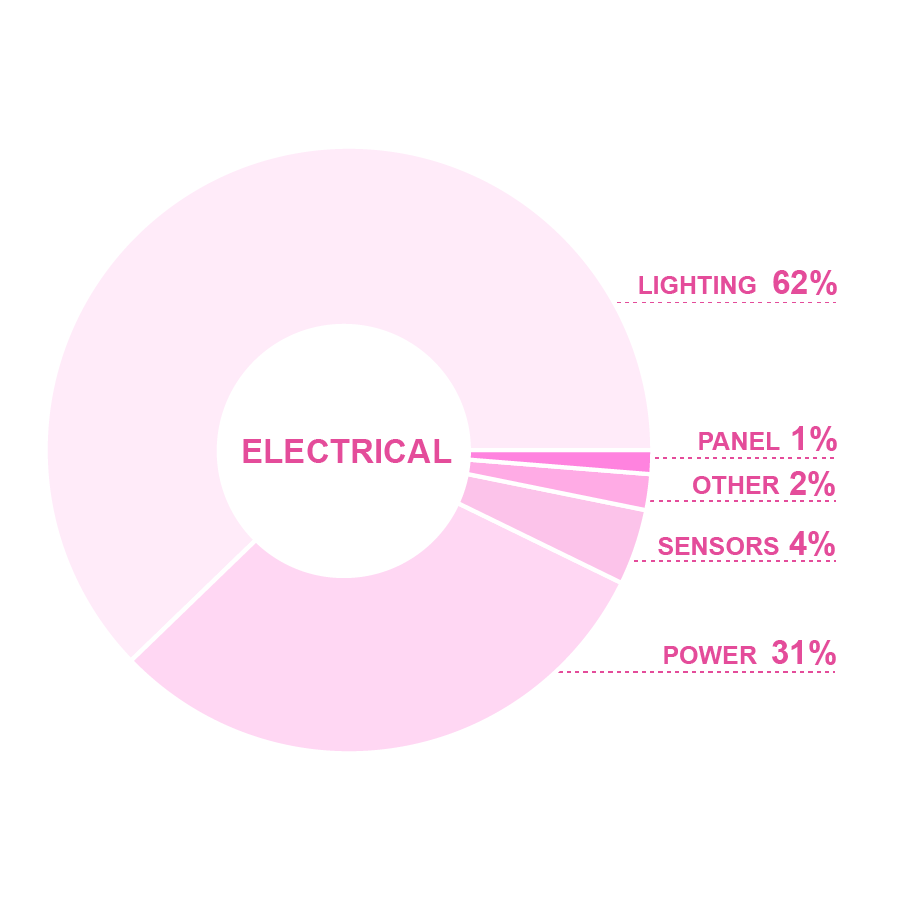

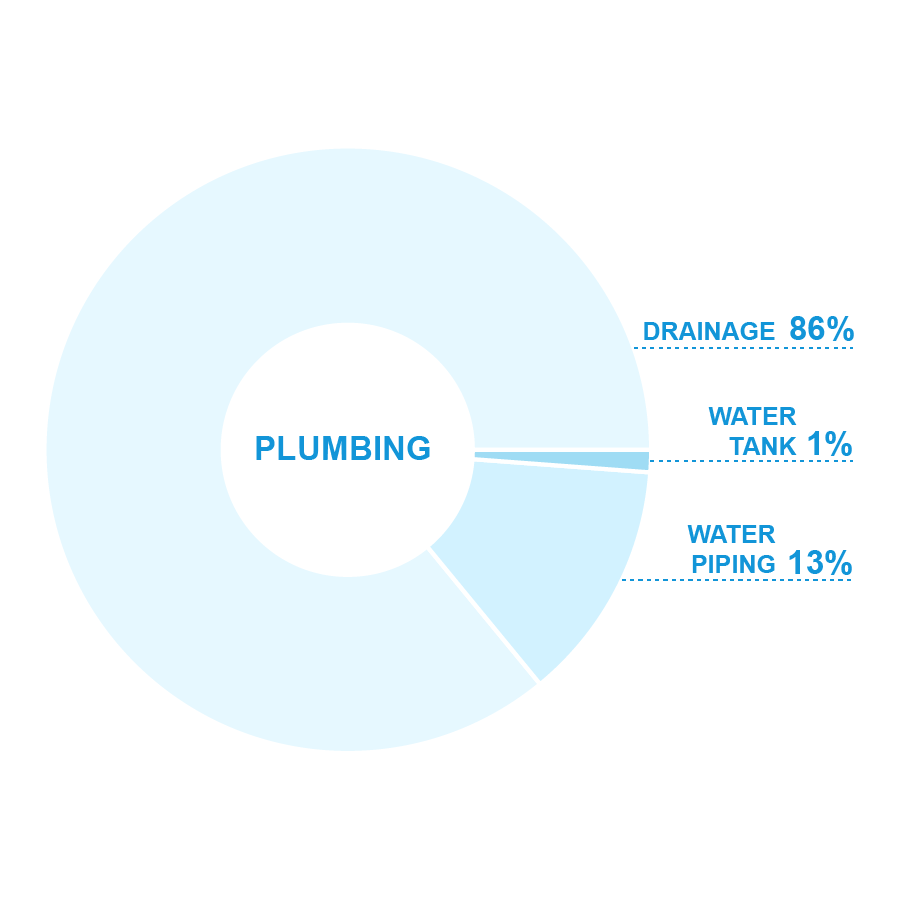

In figure 2 below, the three pie charts show the relative contributions of products within HVAC, electrical, and plumbing systems. The largest contributors are ventilation ducts and refrigerant leakage, lighting and power, and drainage for HVAC, electrical, and plumbing, respectively.

Figure 2. Three pie charts show the carbon contributions of products within HVAC, electrical, and plumbing systems. For HVAC, ventilation ducts at 30% and refrigerant leakage at 50% are the largest contributors. For electrical systems, lighting at 62% and power at 31% are the largest contributors. Finally for plumbing, drainage is by far the largest contributor at 86%.

Roadblocks and Challenges

- Not all locations, designs, or building functions enable passive design.

- While alternative refrigerants exist there is often a premium and limited suppliers. More are expected to be developed and become cost competitive.

- MEP equipment EPD data is limited. Use CIBSE TM65 to request information from manufacturers and estimate embodied carbon for products without published EPDs.

Design Process (Low Carbon vs Usual)

- Concept: Establish goals early.

- Schematic Design and Design Development: Optioneering analysis and programming optimization for passive systems.

- Construction Documentation: Specification and procurement of low-carbon refrigerants and products.

- Construction Administration: Proper installation and maintenance is critical to mitigating leakage.

Lessons Learned

- Passive systems offer both operational and embodied carbon reduction.

- Set project operational and embodied carbon targets at the building and discipline level.

- Continued research into data transparency as well as MEP systems will likely bring additional blind spots to light in the coming years.

Development Team

Architect: Kieran Timberlake

Contractor: Sundt Construction

MEP Engineer: Buro Happold